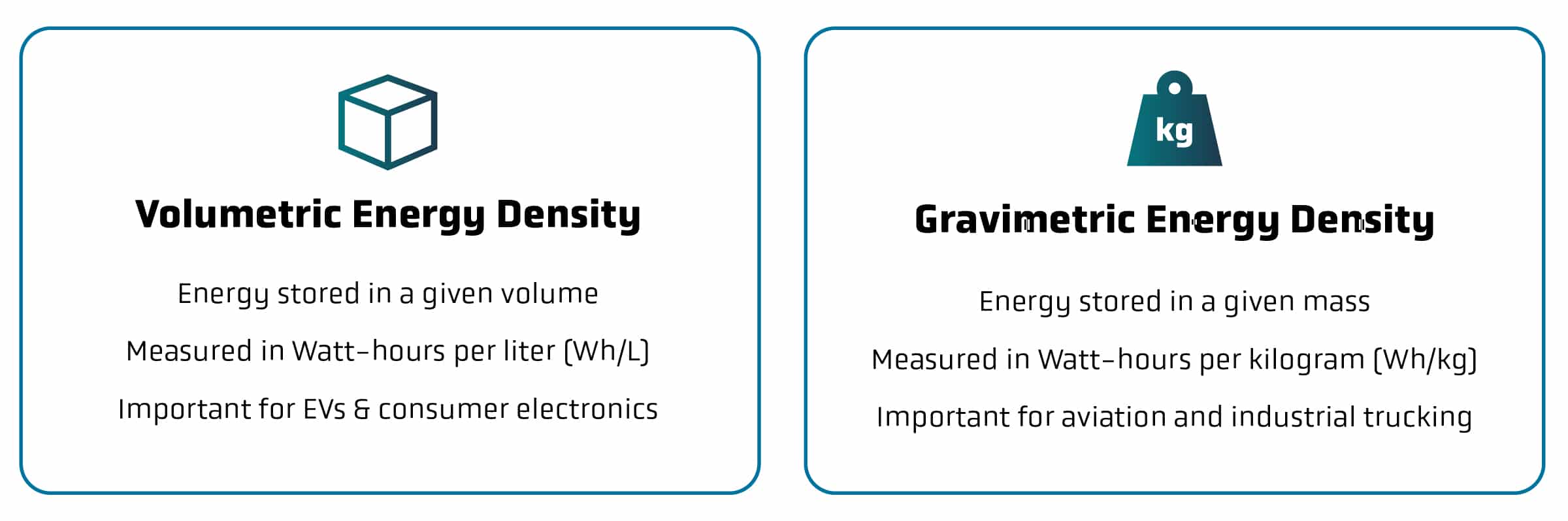

Volumetric energy density

The amount of energy that can fit in a given physical volume is most important for applications that are volume-constrained – where space matters. Consumer electronics and passenger vehicles are two good examples of this.

- Consumer electronics – Users place a lot of value on phones, tablets, and laptops that are thin because they can easily be carried in bags or pockets; famously, when Steve Jobs unveiled the first MacBook Air1, he pulled it out of a manila envelope. But at the same time, users are not willing to compromise on functionality: a device that runs applications quickly and lasts a long time between charges needs a lot of energy to get the job done. Therefore, the more energy that can be stored in a small volume, the better.

- Passenger vehicles – Drivers want as much driving range as possible in their electric vehicles. To add more range in an EV with conventional lithium-ion batteries, the battery pack must be made physically larger, which means the car itself must also be larger. It’s no coincidence that the longest-range EVs on the market today are all full-size sedans: they’re long enough to fit large battery packs underneath. But these large cars are not a good fit for many drivers.

In addition, other popular electric vehicle types, like SUVs and pickup trucks, are already quite large, but due to lower aerodynamic efficiency, offer range that may not satisfy the needs of every driver. Since the vehicles themselves can’t easily be made larger to accommodate more batteries, the battery cells themselves need to pack more energy into the available space. Although weight is also important, for these use cases, better volumetric energy density is a bigger priority.

Gravimetric energy density

Weight is at an absolute premium for applications like drones or aerospace, . In these cases, a bulkier battery can be accommodated by good design, but increased weight always constrains performance, and so the lighter the battery, the better. In extreme cases, such as batteries in satellites, every extra kilogram of weight adds thousands of dollars to the cost of launch.

There are also other applications with more prosaic constraints. In heavy-duty trucking, for example, there are legal maximum weight limits to avoid damaging roadways. For a semi-truck, the math is simple: the less weight taken up by batteries, the more payload can be hauled, and the more the truck can earn per trip. In other use cases, like high-performance sports cars, lighter cars handle better and accelerate faster. For applications like these, gravimetric energy density, also known as specific energy, may represent the bigger pain point.

Why better energy density?

Battery energy density has slowly but steadily increased over the past few decades, and lithium-ion batteries are now so energy dense that they can power electric vehicles for hundreds of miles. After all that progress, what’s the need for an even better battery?

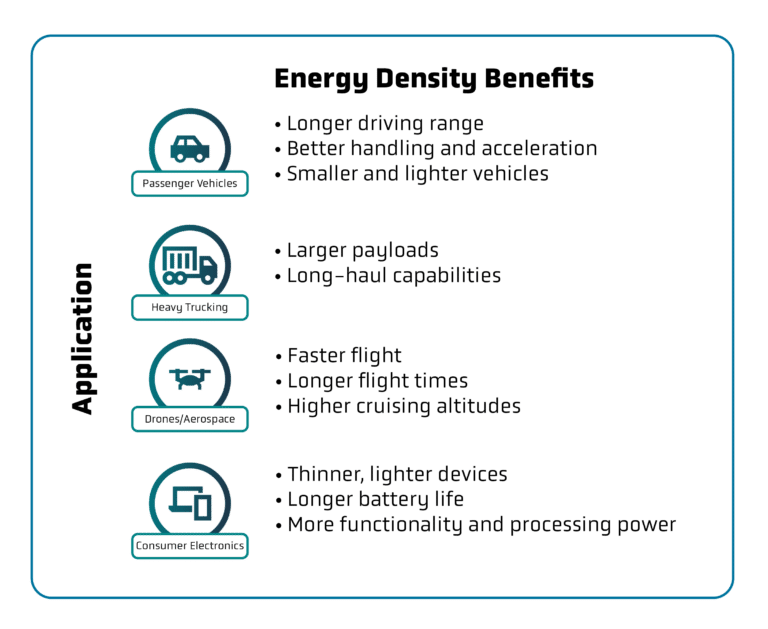

The truth is that, when it comes to energy storage, there is always a use case for better energy density. With better energy density:

- Passenger vehicles can get smaller and lighter, offer more interior space for legroom or cargo, handle and accelerate better, and offer drivers improved efficiency and longer driving range.

- Consumer electronics devices can be made thinner and lighter, run more powerful processors, add additional features, and offer better graphics with snappier interfaces and better screens.

- Drones can fly faster and higher, carrying bigger payloads with better endurance.

- Heavy trucks can service longer routes and carry bigger payloads.

Companies are always competing to offer a car or a laptop or a drone that outperforms the competition, and energy density represents one of the biggest bottlenecks to better performance. In short, better energy density is always in demand.