Bringing a new technology to market can seem mysterious from the outside. Headlines tout “breakthroughs” that never materialize, leaving people skeptical. And yet, technology does advance steadily forward – faster computers, cheaper renewables, and better EVs arrive every year. So what separates hype from true innovation?

At QS, we believe a systematic, methodical and iterative development approach drives long-term success. It’s the same disciplined approach behind the most transformative products of our time – from Ozempic to Nvidia chips to the iPhone. The technology breakthrough is not enough by itself: it has to be amplified.

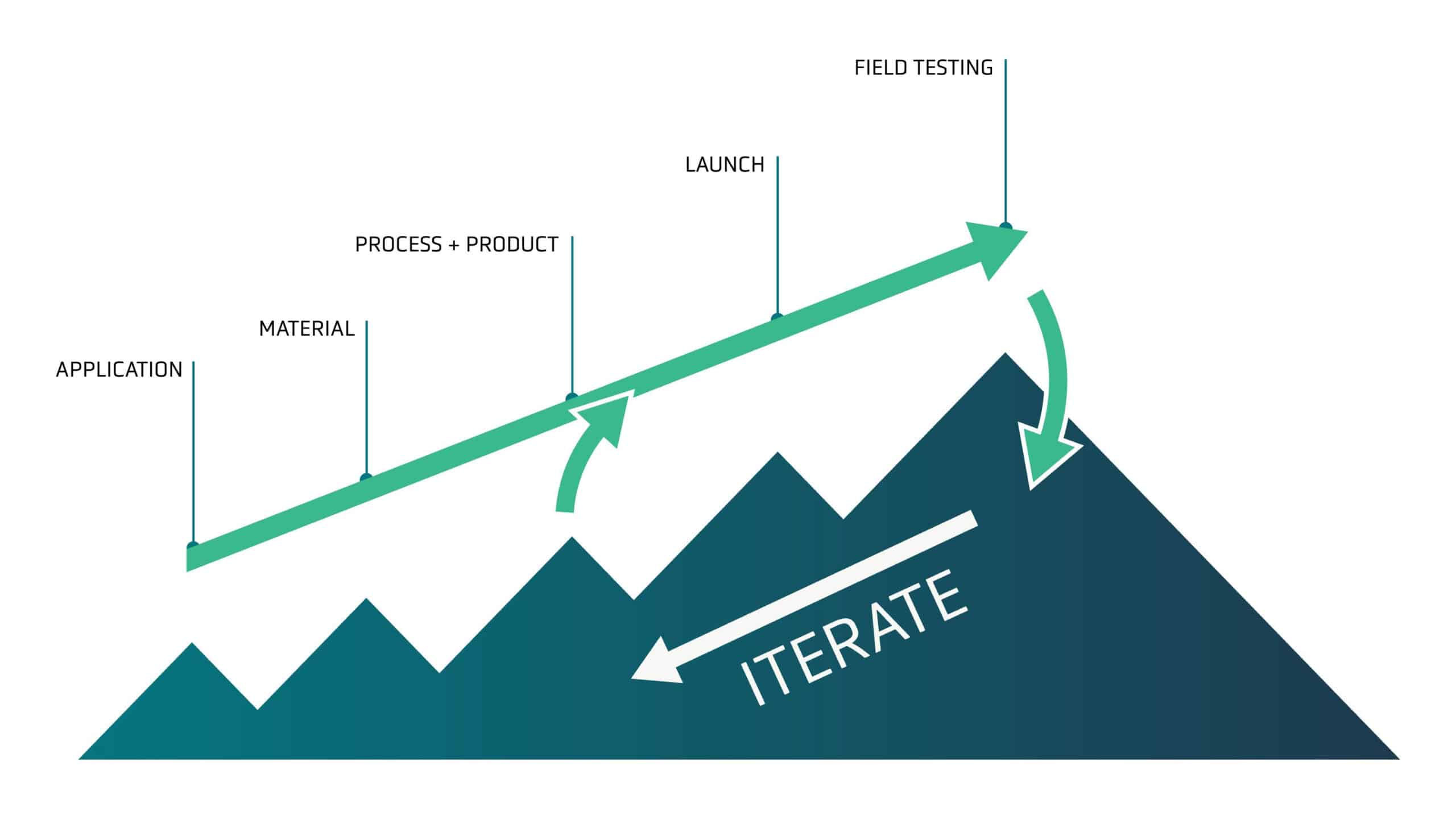

An innovation is only the start of the process – amplifying innovation requires time and discipline to execute properly, but also avoids wasting time and resources on technological dead-ends. Taking technologies from concept to scalable product is like climbing a mountain: you must ensure a secure foothold at each step before taking the next one. Skipping steps and taking shortcuts can end up in disaster.

A is for Application: Define the need

Successful innovations fit a well-defined application. The most sophisticated technology is worthless without a real-world problem and a customer willing to pay for it. Too often, startups and spinouts begin with an interesting technology and then go looking to find a use for it – a strategy that can easily lead to a dead end.

From day one, QS set out to tackle the core limitations of EVs: limited range, slow charging, high costs, short battery life and safety. Our belief was that conventional lithium-ion batteries would incrementally improve over time, but not enough. Solving all those challenges simultaneously would require a fundamental breakthrough.

But building a better EV battery is not easy. To be viable, it must offer high energy density, high discharge power, fast charging capability, operability over a wide temperature range, modest applied pressure, safety and competitive cost at scale. When the application is properly defined, it’s clear that only a no-compromise battery can do the job.

M is for Material: Identify the right thing to make

Once application requirements are defined, the search begins for a material that can deliver on performance. As with many technologies, battery performance is fundamentally driven by materials properties – and the wrong choice can doom a project, no matter its other benefits.

Over our first five years, we rigorously evaluated many options. In the end, only one met the demanding criteria for EVs: a ceramic solid electrolyte that today forms the basis of our proprietary solid-state separator. It’s the material that makes our vision possible.

P is for Process and Product: Making the thing that makes the thing

After the material has been chosen, it must be scaled into a manufacturable product. The product is the physical battery cell, with tightly defined specs. The process is how we make it – the equipment, tools, process steps and quality standards, among much else. Because process and product are so interrelated, they must be developed and specified in tandem.

After many iterations, we developed Cobra, our proprietary continuous-flow high-throughput ceramic manufacturing system. Designed for efficiency and consistency, Cobra represents a breakthrough in ceramic processing tailored for the automotive industry.

On the product side, precision is everything. This work is so painstaking because any small change can have large and unpredictable ripple effects across production, cell design and pack architecture. An issue uncovered late in the game can mean months or even years of additional development work; it’s essential to be methodical and deliberate in every decision.

This careful process led to the QSE-5, our first commercial product. Each design decision was guided by our materials and production design. For example: our anode-free architecture allows us to achieve high energy density even in a relatively small 5 Ah cell. If we had chosen a less lithium-stable material, we’d have needed bulky and expensive lithium-metal foil and a much larger cell design to achieve good energy density, which would also be more difficult to manufacture. That’s the danger of missing a step: you can end up in a technology dead-end.

L is for Launch : Get the product into customer hands

Once the process and product are sufficiently mature, getting a first product to market as quickly as possible is critical. The Minimum Viable Product, (MVP) won’t be perfect but it’s a critical milestone – not the summit, but a new basecamp.

It’s more important to get a product into the market quickly than to make the product perfect in every possible respect. Customer feedback is essential. Launching an MVP starts the feedback loop that drives everything forward.

F is for Field Testing: Carefully measure how the product performs in the real world

Field testing puts the product to the test to gather extensive data on how your first product performs. This is where all the hard work in R&D meets the challenges of practicality. Field testing exposes your product to all sorts of unpredictable conditions that would be difficult to anticipate or simulate in a lab.

For EVs, these are real roads, in real weather, with real wear and tear. You see how the pack design holds up in the real world, how the battery management system should manage the electrical performance of the cells, and how closely the actual performance matches your expectations. Every bump along the way is an opportunity to learn about the robustness of your engineering and product design.

I is for Iterate: Take everything you learned and repeat

Every insight from field testing feeds back into the next version. Maybe a process step can be streamlined; maybe a design tweak yields better efficiency.

This positive feedback loop in the development process is how we amplify innovation. Through the steady accumulation of small improvements, step by painstaking step, a lab-scale technology can grow into a transformative mass-market product with the potential to change the world.