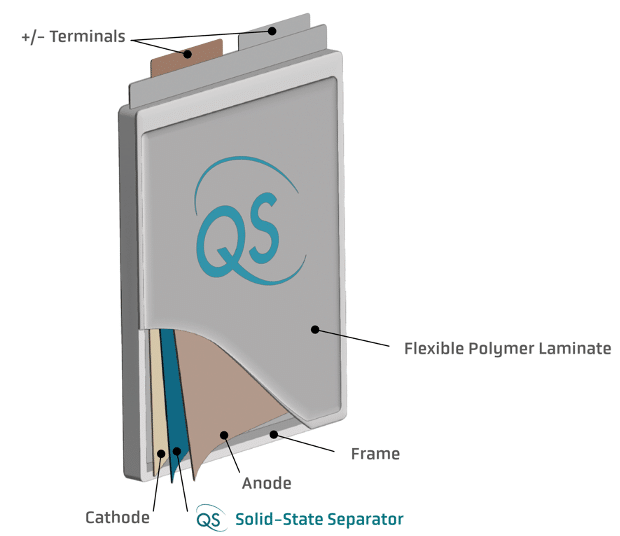

In addition to accommodating expansion and contraction, FlexFrame is designed to allow the cell to simultaneously:

- Dissipate excess heat during fast charging

- Function with or without externally applied pressure

- Enable high-volume manufacturing and pack integration

- Offer good packaging efficiency to achieve our cell-level energy density targets

Temperature

All batteries generate a certain amount of heat during operation, and higher rates of power typically result in more heat. This means that to enable vehicles with quick acceleration and fast charging, you need a battery management system that can quickly pull heat out of the individual battery cells to keep them at their optimal operating temperature. In this context, a high-performance battery cell needs not only good fundamental chemistry, but also intelligent cell design, to enable good thermal performance.

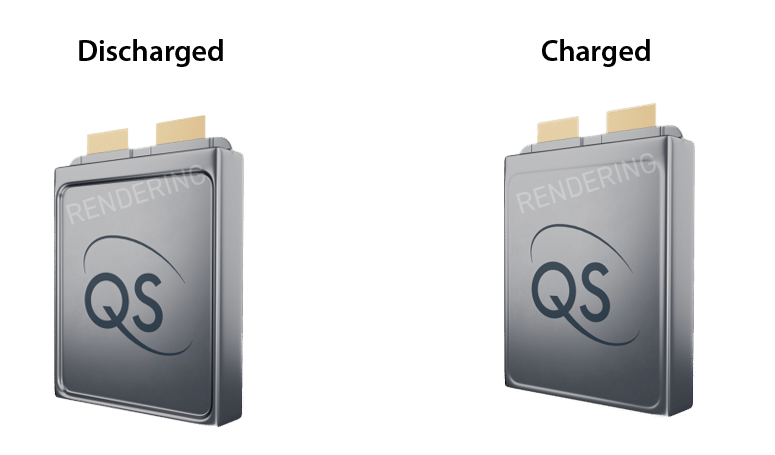

Conventional cell designs all manage heat in more or less the same way: as the cell heats up during operation, the thermal energy must move from the layers of the cell to the external casing, where the pack cooling system draws it away. However, a lithium-metal cell format must expand and contract, and it is difficult to engineer a mechanism, such as a spring or foam, which will both move flexibly and conduct heat effectively from the cell face.

To address this challenge, the FlexFrame design splits these tasks in two. While the exterior face of the cell can expand and contract as necessary, the heat generated can be transferred directly from the individual cell layers to the exterior frame, which can then be cooled from the back or sides. We’re currently working with our partners to develop and validate thermal management systems incorporating our FlexFrame cell design.

Pressure

FlexFrame is designed to work with or without external pressure. If required, pressure can be applied to the external face of the cell, and because heat can be transferred out to the sides of the frame, it’s possible to apply pressure externally while cooling the cell at the same time. However, we have shown data from single-layer cells that demonstrate our lithium-metal platform can deliver long cycle life with zero externally applied pressure, and FlexFrame is intended to be able to operate under these conditions as well.

Manufacturing and pack integration

As a hybrid of conventional prismatic and pouch designs, FlexFrame allows us to leverage tools and materials that are already used in the battery industry. The exterior polymer laminate material is similar to what is found in conventional lithium-ion pouch cells, and the frame gives the cell good mechanical stability, which is provided at the module level for a conventional pouch cell. When assembling the cell, we can use conventional stacking and sealing techniques, which will aid in high-volume manufacturing. And unlike cylindrical cells, FlexFrame cells can fit neatly next to one another with minimal wasted volume, enabling improved overall pack energy density relative to a cylindrical cell format.

Energy density

As discussed in a previous blog, energy density at the cell level is not just about chemistry; packaging also plays an important role. One goal of any cell format is to minimize the amount of dead weight and wasted volume taken up by the inactive materials, such as the cell casing, and maximize the proportion of the cell’s active materials, the part of the cell that actually stores energy. Optimizing this packaging efficiency is key to enabling high cell-level energy density.

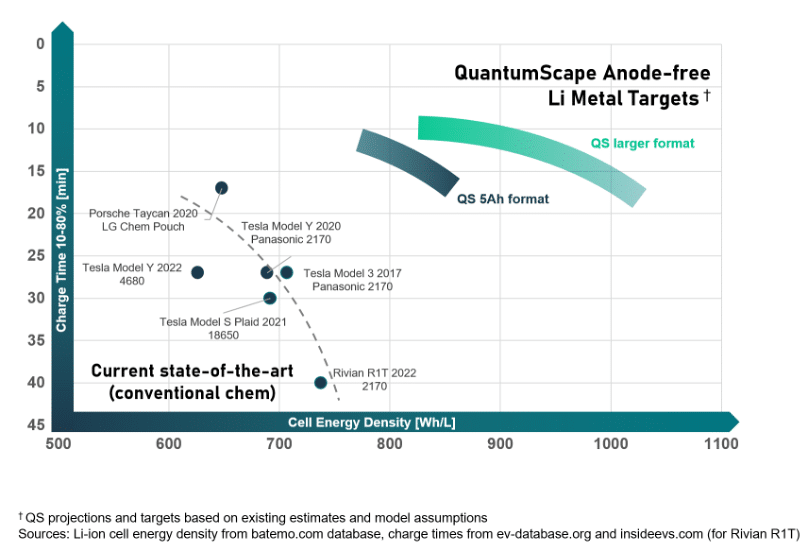

FlexFrame has been designed with this important consideration in mind. Because the lightweight pouch cell material and the low-profile frame add minimal overhead to the cell, we project our new cell format is capable of delivering energy density above 800 Wh/L in QSE-5, our planned 5 amp-hour cell, with significant room for improvement in a higher-capacity design.